Laser Cutting

Overview

Rotas has state of the art Trumatic laser machines, 3kw machines with a 3m x 1.5m cutting bed .

We offer an extensive suite of material with traditional Co2 laser cutting. All of this allows us to offer the

best possible cutting solution, value for money and rapid turnaround times. Laser cutting offers very tight tolerances. Our laser cutting machines are able to cut a wide variety The machines are capable of cutting all types of carbon steel ranging from 0,9mm to 20mm thick, as well as stainless steel ranging from 0,9mm to 20 mm thickness.

Materials including:

- Mild steel, S275, S355JO,S355JR, P355nl1, hot and cold rolled sheets

- Hard wearing plates. Bennox , Th400, Th500, Roq-Last, Roq –tuff,Weldox

- Floor plates or Vastrap / Checker plate

- Stainless steel – 304,310,316 3CR12

- Aluminium – Various grades.

- Spring Steel.

Technical Specifications

Maximum Cutting Size:

- 3000 mm X 1500 mm.

Maximum Thickness

- Mild Steel : 20mm

- Stainless Steel : 20mm

- 3CR12 : 20mm.

- Aluminium : 12mm

Other Information

- +-0.1mm tolerances, dependant on the type and thickness of the material to be processed.

- All parts are deburred before despatch.

Hi-Definition Plasma Cutting

Overview

High Definition plasma cutting offers a cost effective cutting solution to customers seeking moderate to  tight tolerances.

tight tolerances.

We are able to cut a wide variety of materials including:

- Mild steel, S275, S355JO,S355JR, P355nl1, hot and cold rolled sheets.

- Hard wearing plates. Bennox , Th400, Th500, Roq-Last, Roq –tuff,Weldox

- 304,310,316 3CR12

- Aluminium – Various grades.

Technical Specifications

Maximum cutting Size

- 13 000mm X 2 450mm.

Maximum material thickness

- Mild steel 60mm

- Stainless steel 45mm

Other Information

- +- 1mm tolerances, dependant on the type and thickness of the material to be processed.

- Smooth cut surface.

CNC Flame Cutting

Overview

We are able to cut a wide variety of materials using our CNC Flame Cutting machines including:

- Mild steel, S275, S355JO,S355JR, P355nl1, hot and cold rolled sheets.

- Hard wearing plates. Bennox , Th400, Th500, Roq-Last, Roq –tuff,Weldox , Domex

Technical Specifications

Maximum cutting size

- 13000mmx 2 500mm

Maximum material thickness

- Mild Steel : up to 300 mm

Other information

- All cut parts are fettled before despatch

- Up to +/- 2mm cutting tolerance, dependant on material thickness and contours to be cut

- Flattening of plate is done after cutting on request

- Maximum lifting capacity is 10 tonnes

CNC Rolling

Overview

We offer CNC Rolling on state of the art 4 roll set equipment, which offers industry leading accuracy.

Technical Specifications

Maximum material thickness and width

- 3000mm x 50mm thick in mild steel (Much thicker if parts are narrower)

- 3000 mm x 25mm thick in stainless steel (Unlimited thickness if parts are shorter)

- Quenched and Tempered steels – depending on tensile strength up to 25mm thick (Much thicker if parts are narrower).

Other information

- Minimum rolling diameters apply

- Maximum part weight : 10 tonnes

- Tacking and/or welding will be done on rolled parts on request.

Guillotine Cutting

Overview

We are able to cut a wide variety of materials including:

- hot and cold rolled steels in ferrous and non-ferrous metals

- floor plates/ vastrap/ checker plates.

Technical Specifications

- Maximum length : 3 000mm

- Mild steels : up to 12mm thickness

- Stainless steels : up to 10mm thickness

- Flat and Angled bars made to order

Bending

Overview

We offer an extensive suite of Bending machines able to process small to very large parts

Technical Specifications

- Maximum length of part : 4500mm

- Maximum Tonnage : 4 tonnes

- Maximum part weight : 2 tonners

- Angle Measuring system

- 3 point Bending and Air Bending techniques

- Full 3D Software

- Angled bar made to order.

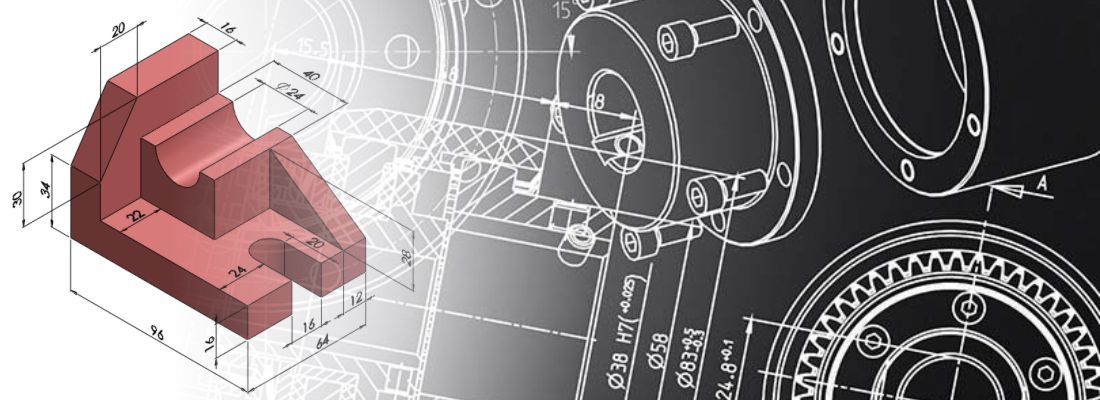

3D Cad Design

Our full in-house CAD Facilities are available to assist customers with drawings, or to nest items to  ensure cost-efficiency. The ability to rotate the part or assembly to any angle and zoom in on even the most minute detail assures correct results first time, every time.

ensure cost-efficiency. The ability to rotate the part or assembly to any angle and zoom in on even the most minute detail assures correct results first time, every time.

Rotas makes use of SigmaNEST, a leading CAD/CAM system for programming multi-torch profile cutting machines. This software improves both material utilization and machine motion, maximizing productivity and cost effectiveness for clients.

Electronic drawing files can be quickly sent via e-mail allowing us to quickly respond to customers’ quote requests, drawing changes and revisions with even greater speed and accuracy.

Rotas Technical Experts can advise you on the most suitable materials to use for specific applications, as many considerations are involved in the correct selection of materials. Factors include the type of materials being haled, abrasion and corrosion resistance, economics and fabrication needs.Our staff can conduct surveys for customers, and assist with in-house trials. This ensures that the best long term results are obtained at all times.

- MasterCam – For all machining programmes for Router Machine (Machining Centre), Drilling and Milling.

- Solidworks – Developments of all Fabrications, Cones, Lobster Backs, Chutes and General Assemblies.